Rolling stock owners and maintainers need look no further than this solid stick wheel flange lubricant which reduces friction, offering longer asset life and lower maintenance costs.

When trains and trams run on their tracks, substantial forces are exerted between the wheel flange and the rail, particularly on curves and bends, causing wear. To address this problem and reduce friction, it has become standard industry practice to lubricate the wheel and/or the track. Ignoring the issue can prove expensive: according to a 2008 estimate, poor wheel-rail lubrication led to extra maintenance costs of up to $10 billion annually in the US alone! Lubrication also considerably dampens noise levels resulting from rail-wheel friction, thus improving the acceptability of tram systems in cities.

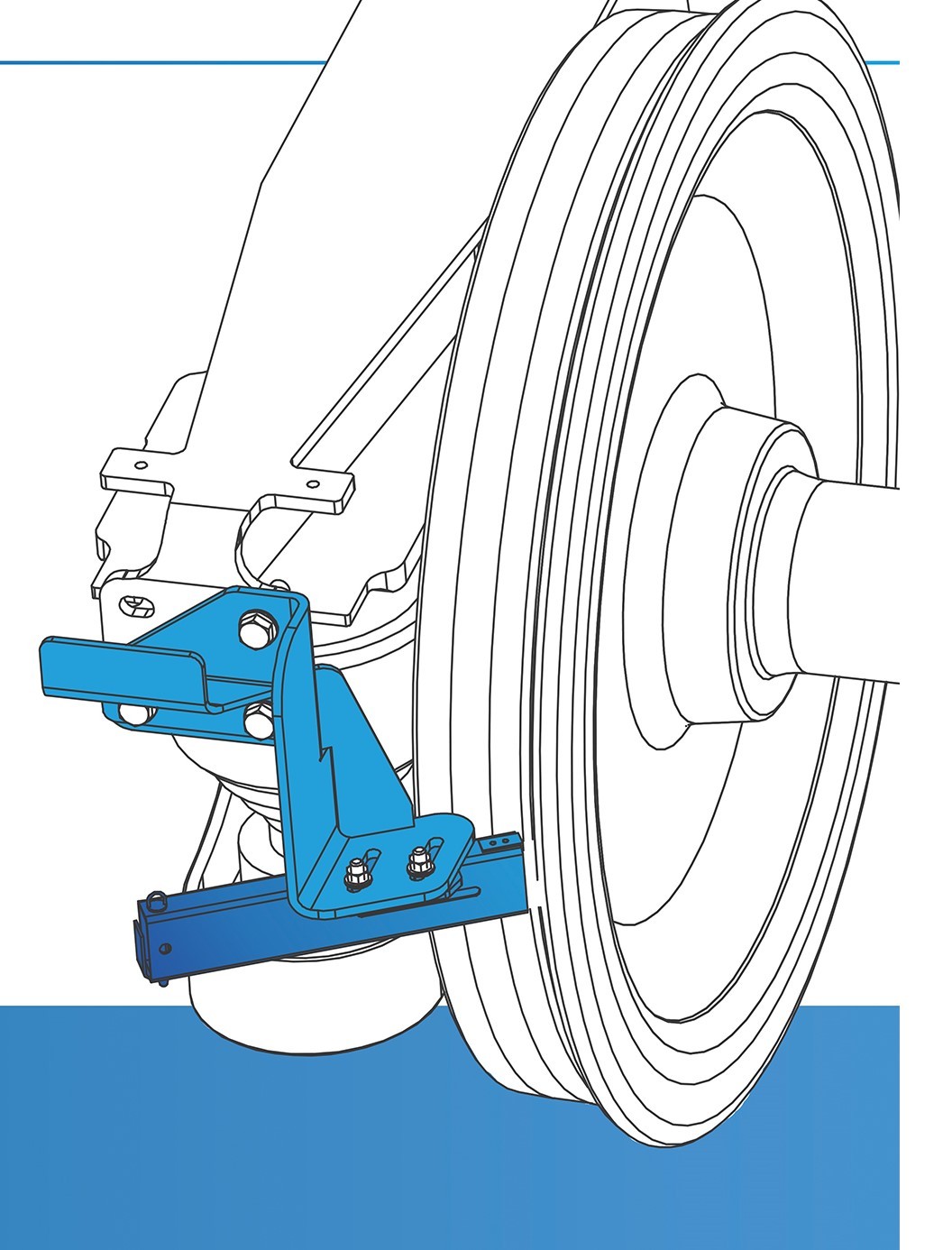

From among the solid and liquid lubrication solutions available on the market, the NSP-WFL soy-based solid stick lubricating system is starting to earn a serious following. Using the simple technology of a spring-loaded applicator mounted on a bracket, both made and sold by Polish firm AW Solutions, the solid stick dispenses the right amount of lubricant onto the wheel flange.

Operators already familiar with solid stick lubrication do not need to make any changes to their hardware, as the soy-based sticks are compatible with the applicators currently sold on the market. For newly-fitted axles, AW Solutions carries out an in-depth assessment of the client’s needs before specifying, manufacturing and fitting the appropriate applicators and mounting brackets.

Technically proven

The eco-friendly, bio-degradable lubricant made by the American firm Natural Soy Products offers the advantage of being resistant to rain, thereby improving its long-term effectiveness, while other wheels running along the track can passively pick up lubricant from the rail.

Meanwhile, NSP-WFL is fully compliant with the requirements of standard EN16028 which specifies friction coefficient levels. Tests conducted by the Silesian University in Katowice also concluded that lubricating the wheel-rail contact with a soy-based product resulted in fewer and smaller, pits and holes on the wheel surface, and that these were characterised as adhesive wear, rather than fatigue wear.

Cost effectiveness friction control

The efficiency of the lubrication and the simplicity of the system combine to offer unbeatable cost-effectiveness. Through lower wheel wear as described above, vehicle maintainers will have less need for wheel profiling. Additionally, as the system can be fitted quickly and easily, initial installation costs are low, while the only moving part in the device, the spring, only needs replacing every two years!

The most noticeable upside, though, is the durability of the solid lubricant itself. “Our clients tell us that our soy-based solid lubricant sticks last almost twice as long as their previous product. In addition to being cheaper, this means lower fleet downtime, as the replacement intervals are longer,” says Bartosz Bomba, business development manager at AW Solutions.

A world to conquer

Since launching in 2013, the solution has made rapid progress on the wheel flange lubrication market. It has already been successfully adopted on all forms of rail transport: metro, tram, passenger rail and freight… and in countries ranging from Portugal, Italy and Wales to UAE, Austria and Poland… and even Malaysia!

To find out more about the benefits and specificities of NSP-WFL, click here to register as a user and visit StationOne now.